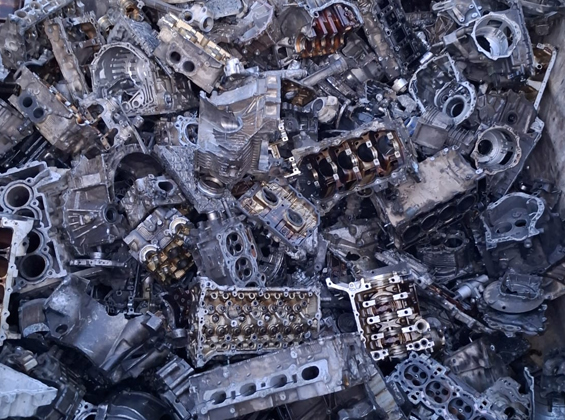

Aluminum Engine Scrap

Aluminum Engine Scrap, commonly referenced by the ISRI code TENSE, represents a highly dense and sought-after grade in the non-ferrous metal recycling industry, primarily comprising whole or disassembled aluminum engine blocks and transmission castings. This specific type of scrap is crucial for secondary aluminum smelters, as its consistent casting alloy composition makes it an ideal, high-yield feedstock for producing new automotive and industrial components. Konark Exim specializes in sourcing and supplying clean, high-density Aluminum Engine Scrap to foundries globally, ensuring a reliable stream of this critical resource that supports efficient furnace operations and the high-precision requirements of modern manufacturing.

Aluminium TENSE Scrap

Aluminium TENSE Scrap is a highly sought-after grade in the non-ferrous recycling market, primarily consisting of mixed aluminum castings, such as complete or partial engine blocks, transmission housings, and other heavy-duty automobile parts. Due to its inherent alloy composition, TENSE is a crucial feedstock for secondary aluminum smelters, where it is melted down to produce new casting alloys required by the automotive and machinery industries. Konark Exim specializes in sourcing and supplying clean, segregated TENSE scrap, ensuring a consistent and reliable supply of high metal-recovery material that enables smelters to maintain efficient furnace operations and achieve precise alloy specifications.

Aluminum Profiles & TT Scrap

Konark Exim provides a diverse portfolio of aluminum scrap crucial for secondary smelting, including the contrasting grades of Aluminum Profiles and TT Scrap (Aluminum Turnings). Aluminum Profiles, sourced from clean window frames and industrial extrusions, offer a dense, high-purity feedstock essential for producing casting and wrought alloys, prized for their low contamination and high metal recovery. Conversely, TT Scrap, consisting of machining chips and shavings, is high in volume and requires expert processing to remove oils and contaminants; Konark Exim ensures this material is clean and consolidated, providing smelters with a consistent supply of both the premium, clean profiles and the reliably processed turnings needed to meet their varied production requirements.